How to use the bubble table

pageview:30

pageview:30

2024.10.25

2024.10.25

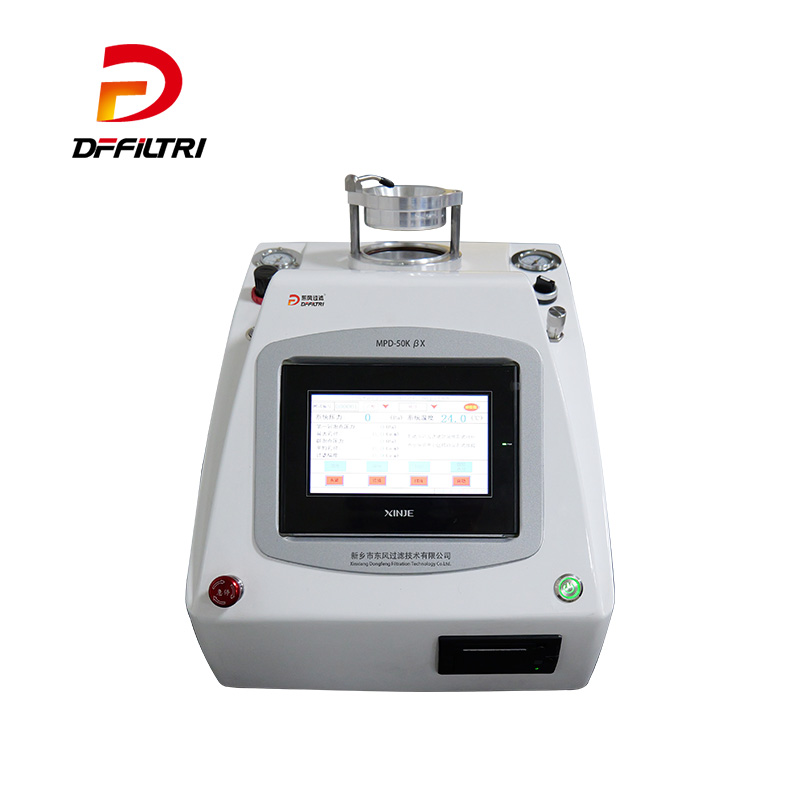

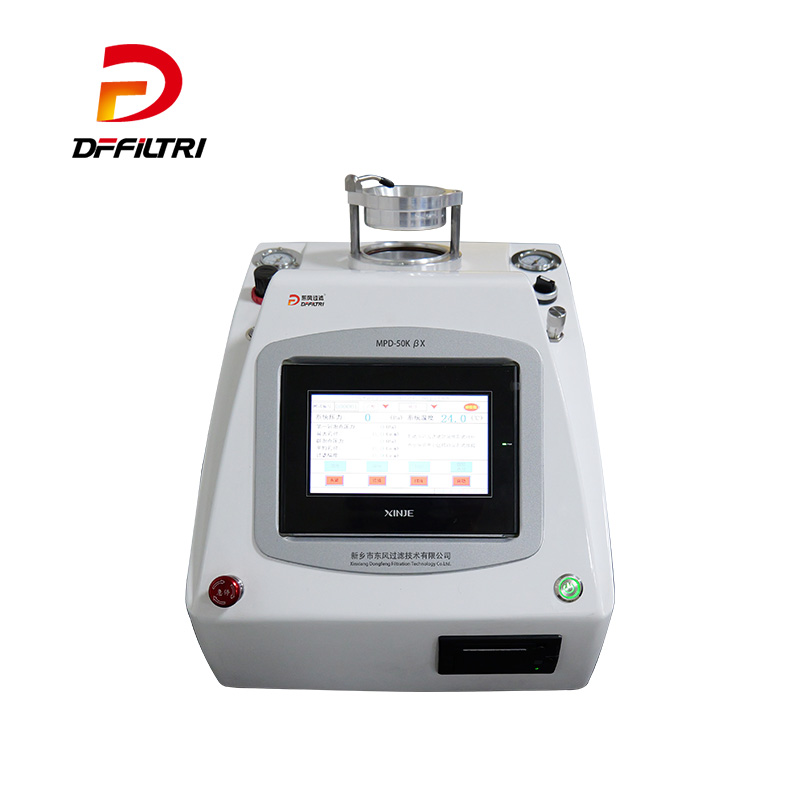

The bubble table is mainly used to test the structural integrity and maximum pore size of filter cartridges or filter materials. Here is a simple way to use the bubble table:

Firstly, ensure that the bubble table is correctly installed and in good working condition. Check if all connection parts are tight to prevent air bubbles from leaking from the connections and affecting the test results.

Next, prepare an appropriate amount of testing medium, such as industrial ethanol or isopropanol, and pour it into the testing slot of the bubbling table. Cut and process the filter element or filter material to be tested according to the requirements, ensuring that the size and shape meet the testing standards.

Then, install the filter element or filter material in the fixture of the bubble table and adjust the fixture to fully immerse it in the test medium. Ensure good sealing between the filter element or filter material and the fixture to prevent leakage of the testing medium.

Next, turn on the air pump of the bubble table and adjust the air pressure. Gradually increase the air pressure until bubbles begin to appear on the surface of the filter element or filter material. At this point, the shape and quantity of bubbles should be carefully observed, and the corresponding pressure values should be recorded.

If there are continuous bubbles on the surface of the filter element or filter material, it indicates that there are structural defects or excessive pore size. At this point, the pressure value when continuous bubbles appear should be recorded and compared with the standard value to evaluate the quality of the filter element or filter material.

After completing the test, turn off the air pump, remove the filter element or filter material from the fixture, and clean the test slot and fixture. Zero the bubble table and turn off the power for future use.

When using a bubble table, attention should be paid to safe operation to avoid accidents. At the same time, the bubble table should be regularly maintained and serviced to ensure that it is in good working condition. By following the above usage method, the quality of the filter element or filter material can be accurately tested, providing strong support for product quality control.

pageview:30

pageview:30

2024.10.25

2024.10.25